Why visit us at bauma?

✓ Solve your wear challenges

✓ See the latest innovations from Hardox® and Strenx®

✓ Learn how SSAB is revolutionizing steelmaking

✓ Connect with leading experts

See how Hardox® 500 Tuf reinvents bucket design

A bucket made entirely in Hardox® 500 Tuf can make bucket engineering and manufacturing more cost-efficient, and improve capacity and durability for the end user. The proof is presented in SSAB’s stand at bauma, in the shape of a real life bucket from the German manufacturer Kaiser.

Hardox® 500 Tuf is part of the full Hardox® experience at Bauma, also showcasing Hardox® HiTemp for hot wear, Hardox® HiAce for corrosive wear, and Hardox® 450 made from SSAB Zero™ for wear resistance with less environmental impact.

Join us at bauma 2025, stand A6.439

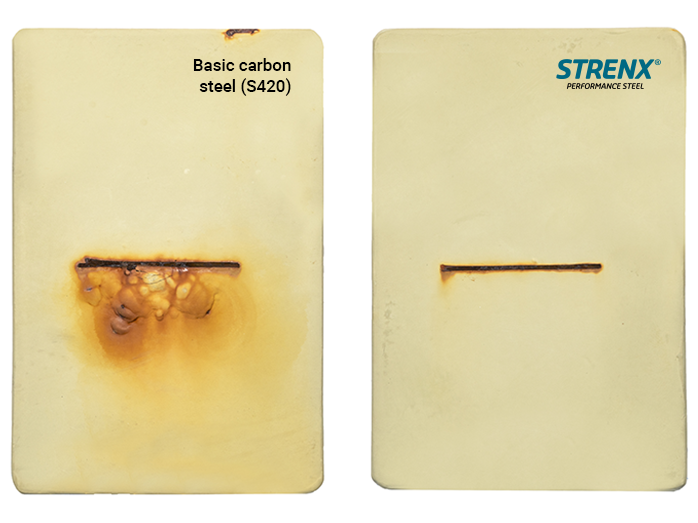

Strenx® Weathering delivers cost-effective and maintenance-free corrosion protection

With the Strenx® Weathering products, SSAB offers a high-strength structural steel that has amazing corrosion protective properties, while also being more cost-effective than galvanized steel. Painted Strenx® Weathering meets the same C5 corrosivity standards as hot dip galvanized steel, all you have to do is paint it. This makes Strenx® Weathering a more cost-effective and environmentally friendly solution throughout your products’ lifetime.

SSAB Zero™ — Enabling sustainable performance

SSAB Zero™ is steel made using recycled steel and fossil-free energy. It has virtually zero fossil emissions during steel production, without mass balancing or allocation of emission reductions or carbon emission offsetting.

The carbon footprint of SSAB Zero™ is third-party verified and published in Environmental Product Declarations (EPDs). And now also available for Hardox 450, the world's most popular wear plate.

Come and touch the steel in our stand A6.439!

Book your bauma meeting with us here

|

|---|