How Hardox® HiAce fights corrosion?

EXCELLENT

Same excellent mechanical properties as Hardox® 450

PROTECT

Equipment from acidic loads

LONGER SERVICE LIFE

2.7 times longer service life when corrosion is present

How global manufacturers talk about their Hardox® HiAce experience

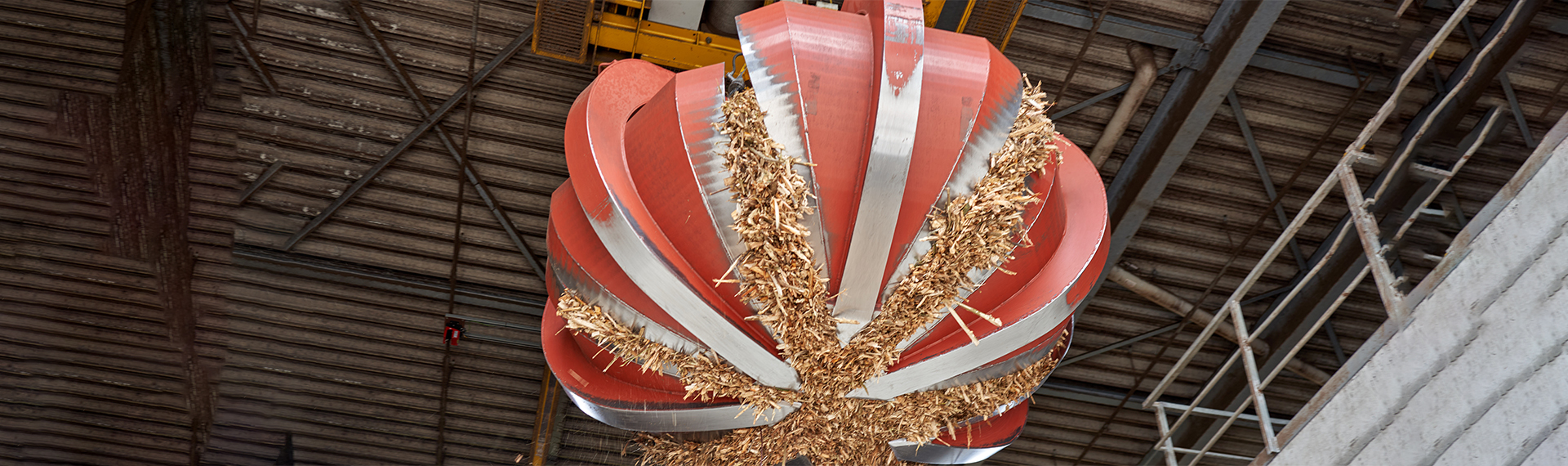

STENA RECYCLING

3 times longer service life for recycling drums made in Hardox® HiAce steel, compared to stainless steel.

Complementary materials